El Cajon, San Diego

Hello!

My vacation is over, the new trainees will soon arrive and it is almost time to leave for our international assignments!

There are many exciting things to look forward to, even though the summer is almost over. As I said, the new trainees will start on 4th of September and it will be fun to get to know them! That means we have less than three weeks left as “this year’s trainees” before we are being replaced. We are trying to maximize the last weeks as trainees: we will go on a fifth and last activity week the week before the new trainees start. We will finish the activity weeks as we started: with a road trip in Sweden (this time we will make a detour to Norway as well).

The whole of September will consist of finishing things in Trollhättan and making the final preparations for the international assignment. If everything goes according to plan, I will be sitting on a plane heading towards USA at the beginning of October. I am going to El Cajon, which is a GKN site just outside San Diego, which in turn is located in the southern-most part of California, approximately 20 minutes from the Mexican border. I have never been to California so I am very excited to live there for half a year. Previous trainees who have been to other GKN sites in California have been very pleased, which I hope will be my experience as well.

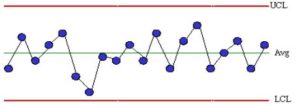

Exactly what I will do in El Cajon is being planned right now, but it will most likely involve projects in CI (Continuous Improvement) and production analyses. I look forward to getting to know the American work culture, to see how it differs from the Swedish and to learn lots of things I can bring back to Sweden.

Sadly enough, this will be my final blog post. It is, however, definitely time to hand over the blog to new people and you will get to know them along the way!

Emelie