NextGen Manufacturing

Hi all,

I have during my latest rotation been at the same department as Emelie, but my task has been out of a different sort where I have focused on Additive Manufacturing (AM).

I have gotten the chance to meet many experts within the field of AM at the company and it has been really rewarding with interesting discussions. Well, discussion is maybe farfetched as I had to spend my full focus on taking notes as I am a rookie within the field of AM. But nevertheless I am really grateful for all the inputs and insights that I have received around the topic of additive manufacturing. I got a whole new view of it in a way that is not possible by reading a book.

Anyhow, some of you might wonder what additive manufacturing is, (pause for suspense) I will tell you. Ordinary manufacturing methods usually involves a subtractive method, which means that you have a big piece of metal that you turn and mill until it gets the form that you desire. Usually a lot of material is used up in the process (removed) which puts a high load on the environment, a load one preferably would eliminate! But nevertheless this method has been the traditional method to use as other options are scarce. This changed when additive manufacturing was introduced to the market, which is the opposite of subtractive manufacturing.

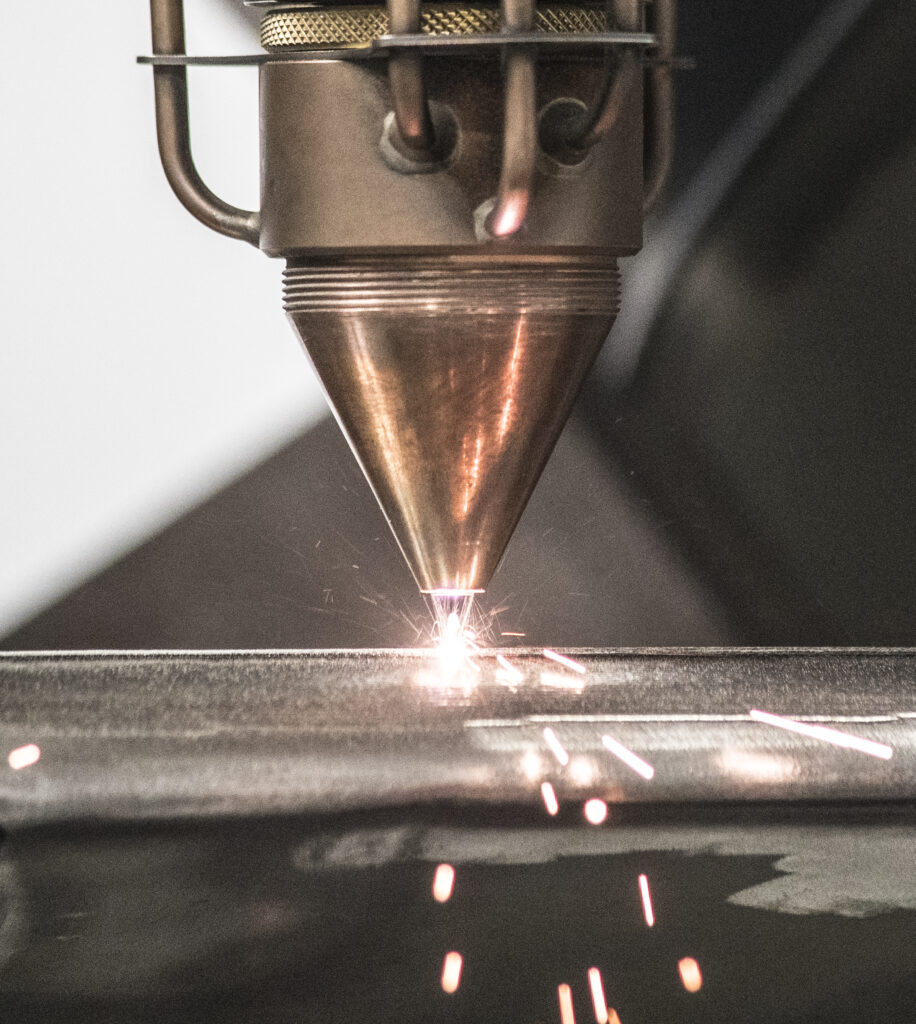

Additive manufacturing works by deposition of layer-by-layer until the desired part has been constructed, which you specify with the help of 3D-CAD. Today, you can perform the manufacturing of parts in some different ways and there exists seven different technologies to perform additive manufacturing. You can construct parts in plastic as well as in metal, however metal manufacturing is still energy intense which is unavoidable. In metal AM there are several different ways in which the material can be added to the manufacturing process, you can do it either with wire or powder. When using wire, you need to add the material locally to the build, where a laser is melting the tip of the wire. Using powder you get two options. You can add it locally just as in wire manufacturing, a nozzle deposits the material locally and a laser then melts the powder in place. You can also use a bed of powder where a laser, or another energy source, then sweeps the bed where the part is to be built and a component emerges towards the end. The part is then build “within” the bed itself. Whichever way you do it, some post-processing is required to achieve the desired finish.

Innovation and technology has always been the forefront at GKN Aerospace where we as a company always strive to attain knowledge and experience within different fields. This enables us to tailor-design a manufacturing process for our product portfolio. For example, we have a goal to construct our space components with the help of AM, which will usher our portfolio into the next generation. If you want to read more about our AM capabilities and goals, you can follow this LINK.