Quality!

After our amazing week in England, we have once again changed departments. I have been working at a quality department for almost a week now. This department supports the whole of GKN in Trollhättan within a number of different areas. One of these areas is making sure that all requirements from customers, standards and governments are met throughout our business. Another area is to develop and update the operation management system we use. The system describes all processes, standards and responsibilities.

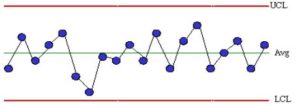

However, during my ten weeks at the department I will mostly work with preemptive production development. This is done by monitoring the manufacturing processes in order to discover trends in the measured product characteristics to be able to solve problems before the product characteristics end up outside the tolerances. One tool that is used are control charts (se picture below).

The upper line illustrates the upper tolerance limit and the lower line illustrates the lower tolerance limit. Once a product has been processed in a machine, the characteristic that was processed is measured and the value is plotted in the control chart. Trends will gradually appear as more products are processed and measured. Is the trend showing that the characteristics are moving towards one of the tolerance limits? If so, the manufacturing process should be investigated to understand why this happens and to rectify the issue. The characteristic is continually measured and hopefully the measured values move towards the middle of the control charts, where they should be.

I find this area very exciting and interesting and I look forward to learn a lot more about it and how it can be used! As I mentioned previously I will mostly work with the production development but I will get the chance to understand what the department is doing in regards to the other areas as well. I am convinced that, no matter what work I will do in the future, I will always be able to benefit from what I am learning at this department!