Servuuus!

The time came for the year 21 to go on their abroad rotation. It was a while ago I wrote a blog post here, and I assume that you may be wondering what has happened since last time? Well, we have managed to do our last domestic rotation in Trollhättan, we’ve had our last development week which was in the US, we’ve managed to visit quite some sites around the world, examples such as US, UK and the Netherlands, but we’ve also got the chance to visit Farnborough Air show last year. When I think about it, quite a lot has actually happened during the two years at GKN, and after our abroad rotations which ends end of June, we return to Sweden and begin our post-graduate positions.

For my abroad rotation, my bags were packed onboard a direct flight to Münich where I’m to work six months with/at our customer ArianeGroup in Ottobrunn. If you read previous posts from last year, you would know that Jens, a graduate before me, went to Vernon in France on his abroad trip, and when I heard about it I just knew I wanted to go there. So when I got the chance, I gladly took it.

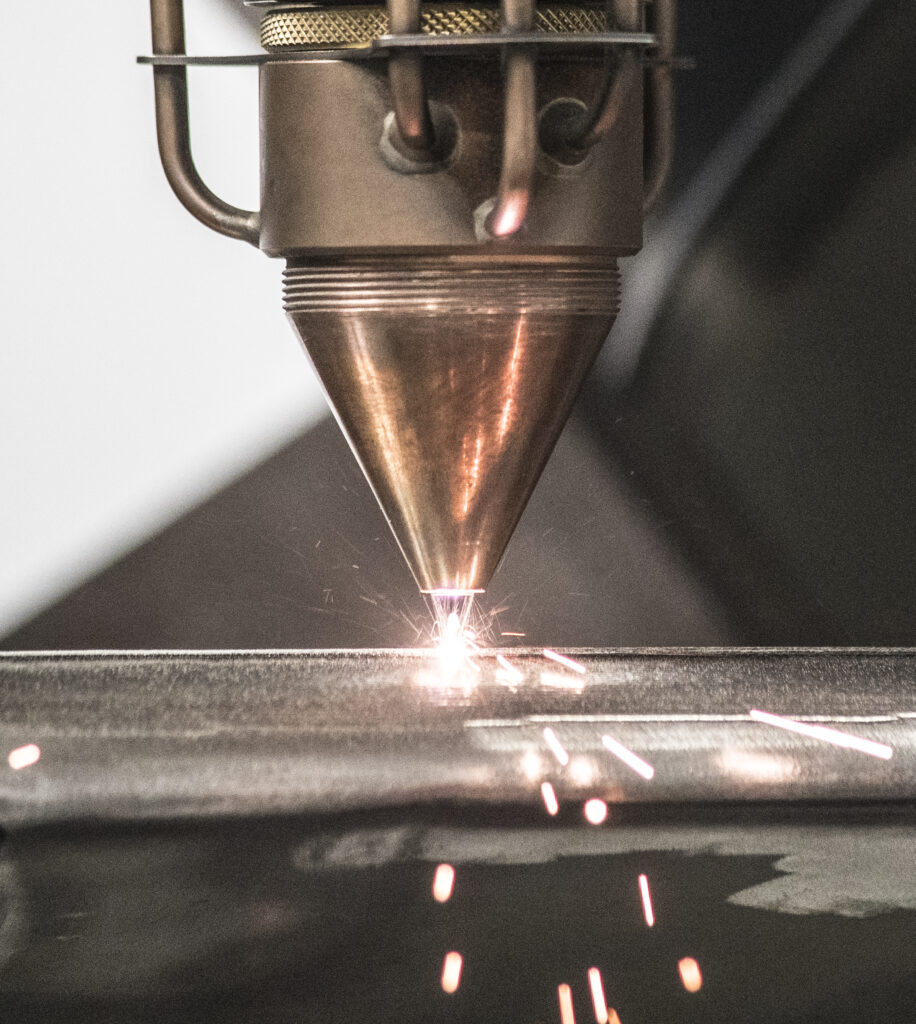

GKN has been a partner with ArianeGroup since the dawn of time (the 80s) and we have been part of every major launcher since then. The last renowned launch you might have heard about was the James Webb Telescope, launched by an Ariane 5. The successor for A5 is the Ariane 6, which is still in development, and for the future, we have the Prometheus project.

So for my abroad rotation, I’ve been involved in precisely that, the Prometheus project, where I’ve had to work with conceptual design on parts of the engine, which has meant a lot of CFD and design iterations. The people here at Ottobrunn are experts within the field of combustion chambers so I’ve situated myself pretty well here. It is a very exiting assignment, and being a space nerd, I feel that I have found the correct spot to be.

Except for working, I am also accompanied here by Elias, who is doing his abroad assignment at GKN Aerospace in Münich, where we are experiencing Bavaria. I really do enjoy hiking so I have forced Elias with me on some trips, pictures are below. To be in Münich is golden, you are very close to some pretty nice destinations. You have Italy, Austria, Switzerland, France and so on very close by but you also have the Alps very near, and of course the food here is not so bad. Golden to say the least.

I could talk longer about my experiences here, but I think this sums it up pretty well. If you have any questions, please feel free to ask!

Until we meet!