Visit at Fokker Aerostructures

As you have read in previous blog posts we graduates had the opportunity to visit interesting companies around Europe before going on Christmas holidays. We have travelled countless miles together in our mini-van, closer to 4000 km (!), where our second stop was in Papendrecht, Netherlands.

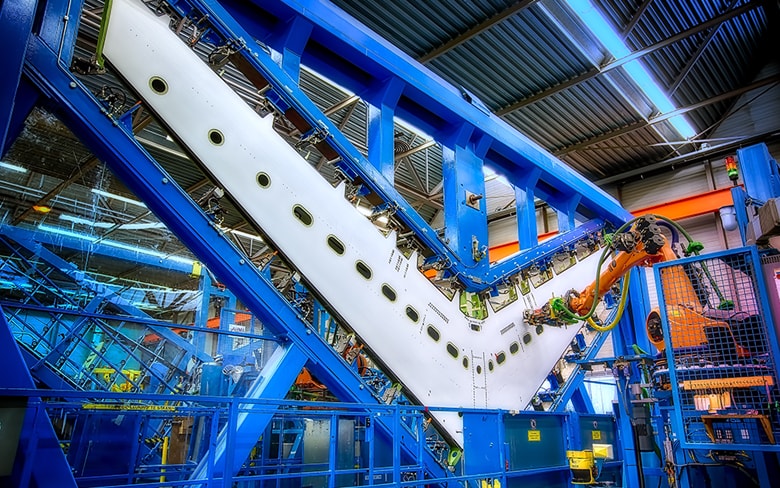

Of course, we wanted to take the opportunity to visit Fokker Aerostructures which have been a part of GKN Aerospace since 2015. We were met by Leo Mujis, Senior Manufacturing Engineer and general go-to-guy, who has a long and impressive experience within Fokker. He told about the company and its history and showed us around the production area. Fokker are leaders in manufacturing of empennages for business jets which we also got to see, impressive!

Not to forget, Kasper and Signe also held a presentation about GKN Aerospace Sweden! Fokker wanted to hear about Engine Systems and what we do, which we more than happily did! They made a poster prior to our visit, look how dashing ;). We also got to meet Tim Jansen, Senior Engineer Specialist Stress, who very kindly had organized for the presentation. Around 30 engineers participated and asked a lot of curious questions. It was very much appreciated to meet colleagues from Fokker we must say!

During this time, Netherlands got an unexpected winter and raised a red alert, which unfortunately meant that we could not meet our graduate colleague Andreas Åhwall, who works at Fokker in Papendrecht at the moment, since he was stuck elsewhere due to a cancelled flight. We had all looked forward to be his guests, but instead had to rent a small holiday house close by. Despite all, fun adventures!

/Lisa