An American Abroad: Part 2, The Frozen North!

Hey blog readers! It’s Zenas Del Rosario again—your friendly, neighborhood, American trainee. As you all know, on top of the challenges that everyone faces during the work-week, we trainees must undergo those same trials far from home for our international assignments. You may wonder what happens during the holidays while we’re abroad. Many of us test our products as we fly home to be with family; others wander into the great unknown and explore their host-countries. I’m happy to tell you that I chose the latter! So strap-in, sit tight, and allow me to regale you with my tale of adventure, intrigue, and what you could do off-the-clock as a trainee at GKN Aerospace!

And so began my adventure! Highly recommended by my Swedish friends and colleagues, I was headed into the Great Frozen North, the Arctic Circle of Grandeur, the Land of Snowy Wonders—the great city of Kiruna! I set out from Trollhättan on the Polar Express armed with nothing but my backpack of supplies and a phone filled with podcasts before enduring a 22 HOUR TRAIN RIDE. Yes, I was told to fly. No, I didn’t listen. Seat soreness aside, I was awe-struck by the snowy country sides, sleepy towns, and frozen forests that cover Sweden’s northern expanse. Like something out of a story book, I was once again amazed by Sweden’s beauty—second only to America’s! As the sun set at 2pm on Christmas Eve, the train pulled into Kiruna station; and so I gathered my things, stretched my legs, and bundled up before stepping out into the cold.

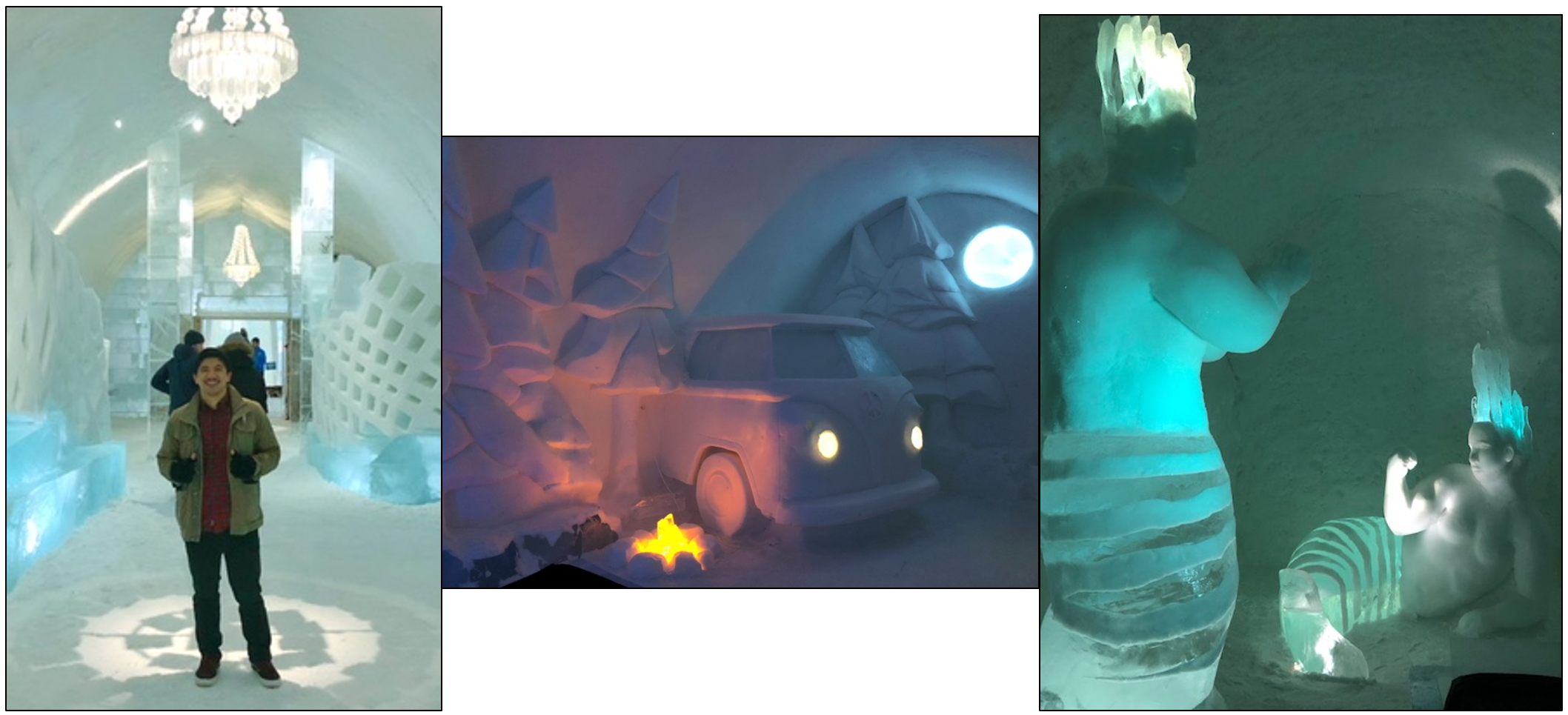

Well rested and raring to go, I awoke on Christmas morning with a sense of childish whimsy. Having never spent a winter further north than sunny San Diego, I threw open the curtains of my hotel room and basked in the sight of the white Christmas I had always dreamed of! With snow as far as the eye could see, I dressed quickly and set out to accomplish the first thing on my touristy to-do list. I hopped into a taxi thankful that the heater was on full-blast and watched the sites fly by as I rode to Santa’s unofficial, favorite vacation home—the world famous, original ICEHOTEL. I could tell you all about the amazing vaulted ceilings, one-of-a-kind sculptures, and intricate designs all carved out of ice, but a picture’s worth a thousand words so here you go…

Unfortunately, I didn’t get to meet Santa on vacation. I hear he was still at work somewhere over Hawaii when I visited the ICEHOTEL. I wasn’t too sad about it though. With my epic day near completion, I headed back to Kiruna for dinner and indulged in one of Sweden’s lesser known delicacies…

Being the good Catholic dude that I am, I couldn’t end my Christmas break without checking in on the birthday boy—my homie and Lord and Savior, Jesus Christ. Before leaving on my journey back to Trollhättan, I made sure to stop by his gothic-style winter home to thank him for all the good that he allows me to do. He gave me a quick pep talk, made me promise to keep on keeping on, and sent me on my merry way.

As the saying goes, all work and no play makes Zenas a dull boy. The trainees and I work extremely hard to make things fly; but as you can see, even we find time to maintain a healthy work-life balance. If you’re reading this and want your chance to earn a spot on this amazing roster of professionals, take a swing and apply today! Until next time, gotta fly.