HR placement in Bristol, England

Hello everyone!

As you already know, me and the other 2020/2022 graduates are all abroad for our last placements, where I as well as Emma ended up in Bristol. Maybe you remember the news about Eunice hitting UK, the worst storm in decades? That’s when I arrived. Luckily the weather have just gotten better ever since and we’ve finally good some nice warmer summer weather, even if it looks like we’re getting a bit of rain now for Midsummer. But hey, what is Midsummer without rain anyways?

Since I arrived here in UK I’ve been working in Human Recourses where I am part of the global Talent and Engagement team. I am based at the Global Technology Centre here in Bristol and the rest of the team is spread across England. Luckily we’ve learnt a lot about remote working and digital meetings lately! The work in HR is totally new and very different from any other work I’ve ever done but I’m learning so much. Since I arrived my time have been divided into two major topics, events and Learning & Development. With Learning & Development my work have been heavily focused on the “behind the scenes” in our Learning Management Systems, Wilbur and LinkedIn Learning.

The first event I got involved in was Recognition of Learning, a ceremony at the Aerospace Museum in Bristol. Under the wings of the Concorde we recognised colleagues within our company for their achievements during the past two years and as part of this celebration the 2019/2021 global graduates also had their graduation. During the same week the 2021/2023 global graduates also had their first development week, which Moa has already told you about, which made it a quite intense week and start of my placement but so much fun and a lot of good memories made!

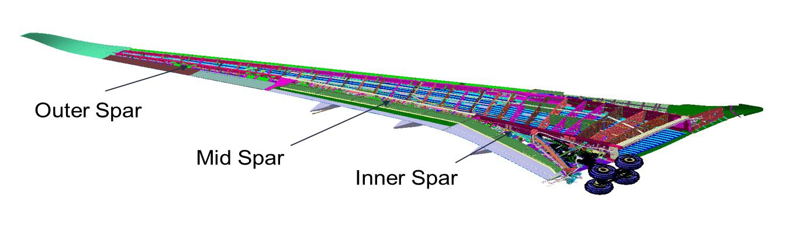

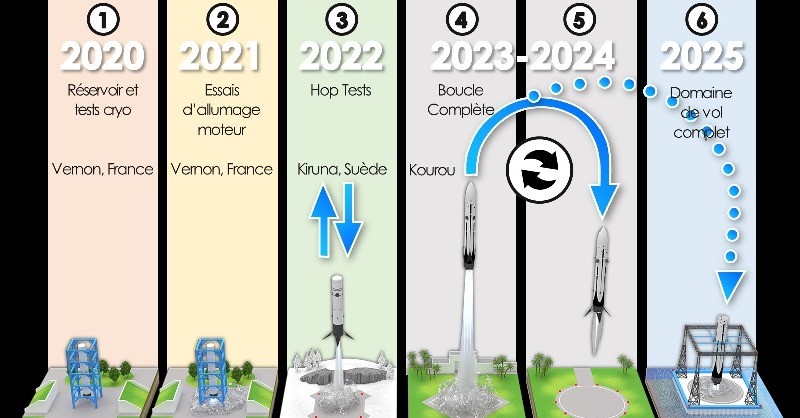

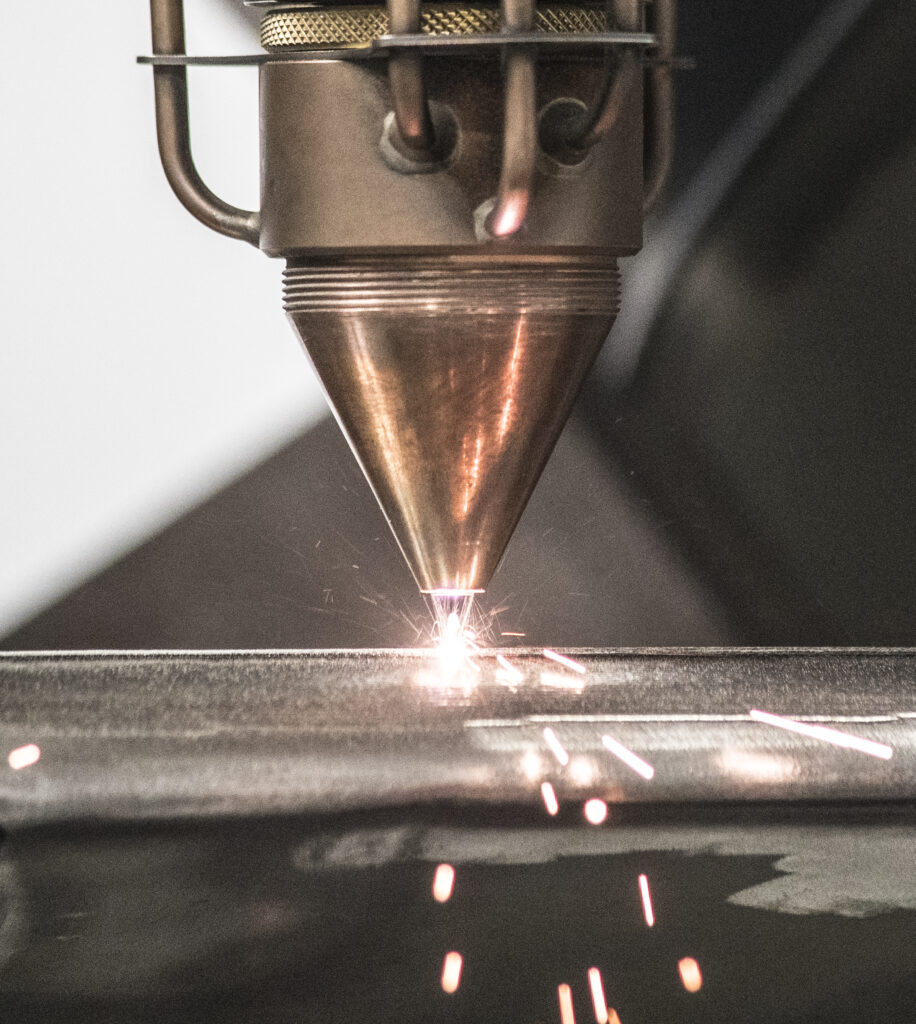

After this big event in March it was a quieter month in April before me, Emma, Jens and Marcus went to Paris early May and then adding in Robin for our third development week in US just a few weeks later. First thing first, Paris and the JEC World. JEC World is an international composite show where we as graduates helped out in the GKN Aerospace stand as well as walking around the show getting inspired from all the other exhibitors. We gathered new knowledge around composites and our products and I am truly grateful for this network experience!

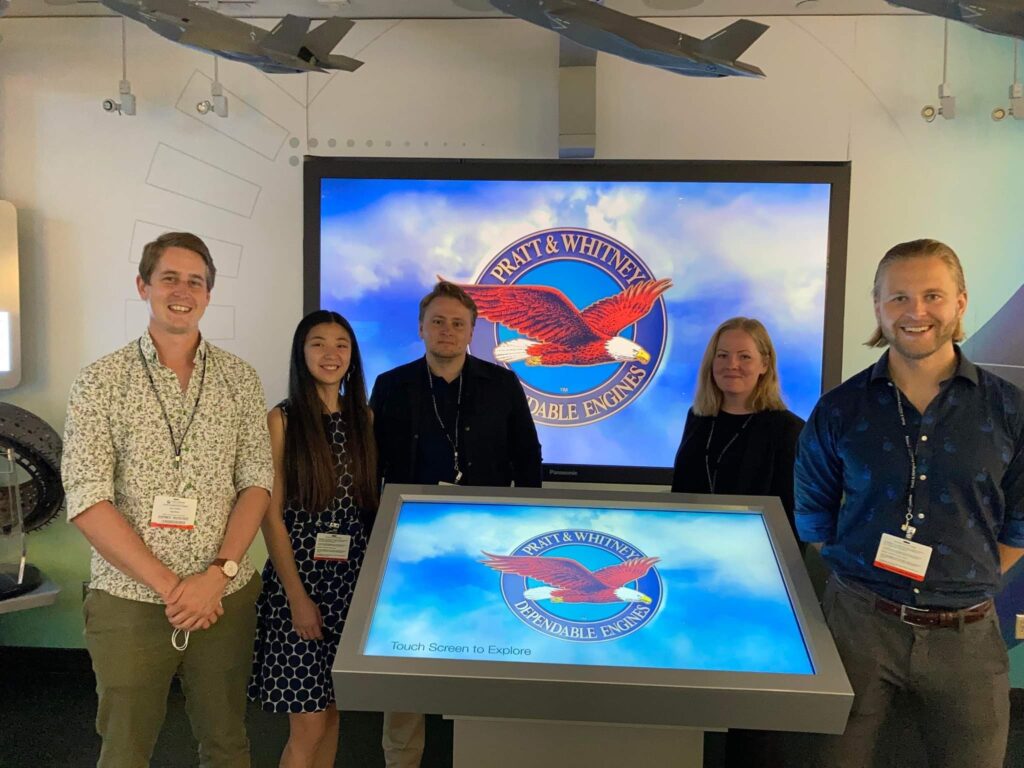

After a week of recharge back home in Bristol my graduate cohort met up for our third and final development week at our Newington site in Connecticut. During the week we developed skills and knowledge around coaching, presentations and negotiations and between the sessions we got the pleasure to meet the US recruitment team and Engines Talent team, and also throw some axes! Before leaving US we also took the opportunity to visit Pratt & Whitney’s Customer Training Centre where we got to see our products assembled on to the engines. Then of course we ended our trip with a visit to the Intrepid Sea, Air & Space Museum in a sunny New York!

I can’t understand where time has gone. We’ve soon been here for two years which means that we’ll be graduating this autumn. I just want to take the opportunity to thank my cohort for everything, what a journey it’s been! But before ending the scheme and leaving UK I will end my placement with a last project, Farnborough International Airshow, one of the world’s biggest aerospace events! All the global graduates from both 2020/2022 and 2021/2023 are meeting up here in UK for this, so I bet you will hear more about it later on!

Have a great summer everyone!

/My